Phantom ER Collets DIN 6499 B / ISO 15488 B

Phantom ER collets have been internally and externally ground and finished to an ultra fine standard, achieving a roughness < Rz 2.5. Phantom collets have a large clamping range of up to -1 mm and a hardness of HRc 45+2.

Phantom can supply the following collets for various applications.

ER standard collet

Centring accuracy < 0.015 mm

This standard collet is used for round-shank tools.

ER ultra precision collet

Centring accuracy < 0.005 mm

This collet is used when high precision is required, such as when using SC tools, drilling and milling operations and reaming.

ER rubber-sealed precision collet

Centring accuracy < 0.008 mm

Sealing up to max. 40 bar

This collet is used for round-shank tools with internal cooling. Due to the smaller clamping range, the bore of the collet needs to match the shank diameter of the tool.

ER mechanically sealed precision collet

Centring accuracy < 0.008 mm

Sealing up to max. 120 bar

This collet is used for round-shank tools with internal cooling and where a pressure higher than 40 bar is applied, e.g. gun drills.

Due to the smaller clamping range, the bore of the collet needs to match the shank diameter of the tool.

ER rubber-sealed "Coolant Jet Precision" collet

Centring accuracy < 0.008 mm

Sealing up to max. 40 bar

This collet has additional cooling channels in the collet to enable the tools to be used without internal cooling.

Due to the smaller clamping range, the bore of the collet needs to match the shank diameter of the tool.

ER tap collet

Centring accuracy < 0.008 mm

This collet is designed for use with taps. Features a square tap socket to prevent twisting in the collet.

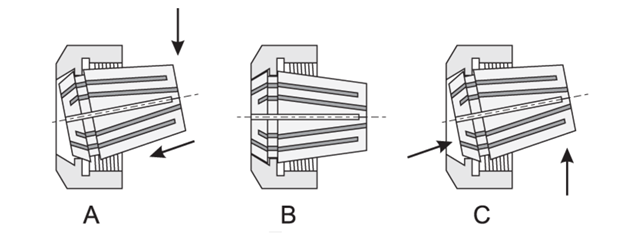

A- Insert the collet into the collet nut, turn until the eccentric ring falls into the groove of the collet. Next, press the collet in the direction of the arrows until it clicks into the nut.

B- Insert the collet and collet nut together into the collet chuck.

Next, once the shank has been cleaned, the tool can be inserted into the collet and the nut can be tightened.

C- To dismantle the tool, loosen the nut using a spanner and the collet will be pulled out of the collet chuck by the eccentric ring. Remove the tool from the collet and completely unscrew the nut and collet from the chuck.

The collet can be removed from the nut by pressing in the direction of the arrows.

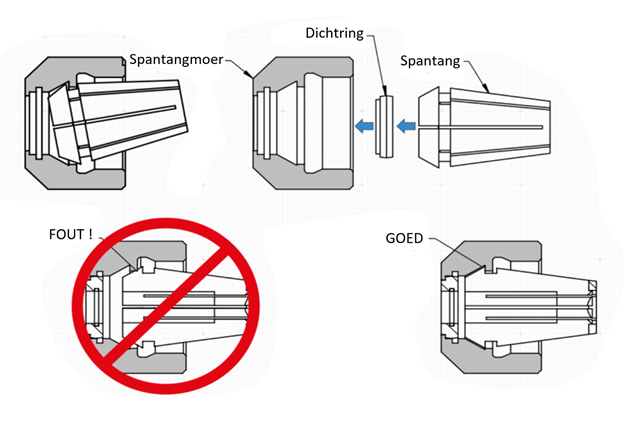

Spantangmoer met afdichtring

Tips & Tricks

BEFORE USE

• Check the collets for damage. Damaged collets cause damage to tools and holders, as well as poor centring.

• Check the collets for rust. Even after they have been scoured clean, rusty collets cause more friction inside the holder, thereby reducing clamping force.

• Clean and dry the collets before use. If there is oil on the inside of the collet, tool clamping may be impaired.

• Thoroughly clean the shank of the tool before inserting it into the collet.

DURING USE

• Insert the tool inside the collet across the entire (or at least two thirds) clamping range.

• Never clamp on the tool helix.

• Ensure that any Weldon surface sits entirely in the collet.

• Ensure that the slits of the collet are not fully closed. If this is the case, the collet diameter is too great for the tool selected.

• Ensure that the slits of the collet are evenly distributed. If this is not the case, the tools is not centrically tightened. Check the cause and retighten.

• While manually tightening the nut, tap against the shank using a copper or plastic hammer. The collet will sit better, guaranteeing improved centring.

AFTER USE

• Clean and dry the collets after use.

• After cleaning, spray the collets using an anti-corrosion agent to improve lifespan.

See the range of Phantom ER collets here.